The foundation of Idroteck

1989

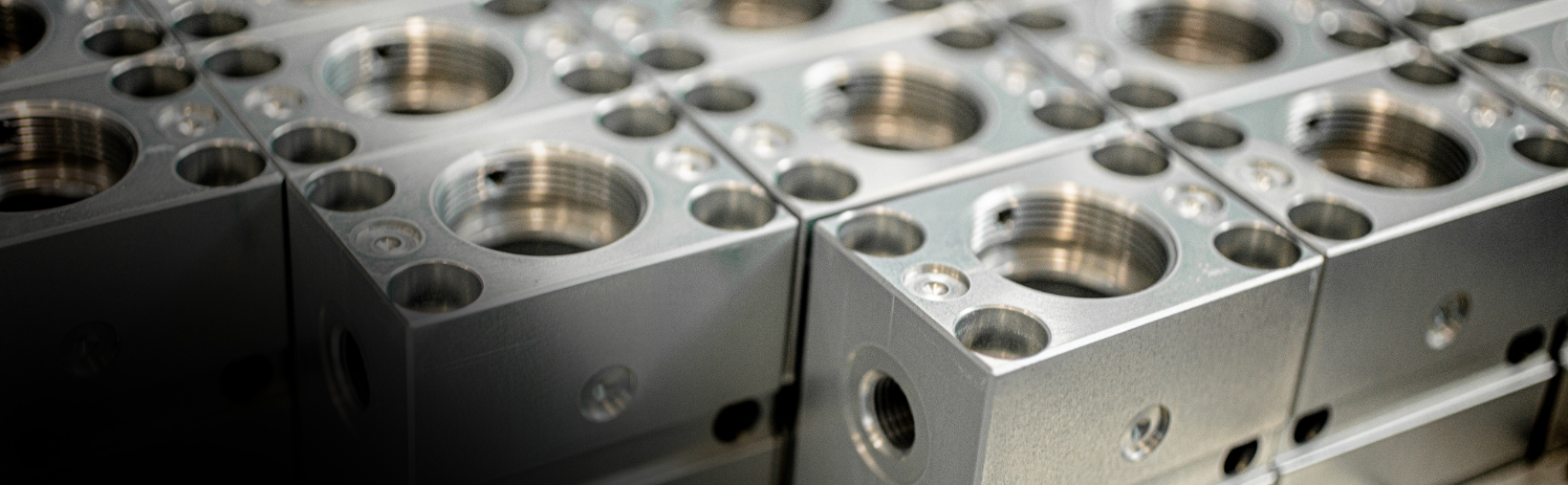

Idroteck is founded in 1989 with the aim of designing and manufacturing high-quality hydraulic cylinders. With its dedication and passion for the sector, the company quickly establishes itself as a benchmark in the industrial, automation, robotics, machine tool, plastic material moulding and pharmaceutical markets.

The introduction of ISO standards

1994

In 1994, Idroteck begins manufacturing tie-rod cylinders in accordance with the ISO 6020/2, standard, consolidating its commitment to internationally recognised quality standards.

A new plant for growth

2001

With growing market demand, Idroteck moves to a new 1,400 square metre plant. This expansion marks the beginning of a new development phase, with the introduction of new machinery such as vertical machining centres and self-learning lathes.

ISO 9001 certification

2008

The achievement of ISO 9001 certification demonstrates Idroteck's commitment to ensuring consistent quality at every stage of the production process, from design to delivery.

Technological innovation

2009-2015

During these years, the company invests in advanced technologies to improve production efficiency. Four INVENTOR 3D CAD stations are installed and the PDM (Product Data Management) system is implemented to optimise technical data management.

Warehouse expansion

2016

In 2016, Idroteck expands its factory with an additional 1,200 square metres. of space. This expansion will allow for the installation of new advanced technologies in the coming years, including automatic vertical warehouses for the management of raw and semi-finished materials, a CNC lathe with twin spindles and Y-axis, and a chain coating system.

Purchase of 3 Modula automatic warehouses

2017

Idroteck adds three Modula automatic warehouses within the plant. This implementation is a further step forward in optimising materials management, as well as improving the organisation and efficiency of production processes. The warehouses allow raw materials, semi-finished products and small parts to be stocked and handled quickly and safely, supporting the company's growth

Renovated spaces for shared growth

2018

The renovation of the offices in 2018 introduces new spaces dedicated to collaboration, including a meeting room and a course training room. This reflects the importance Idroteck gives to training and the active participation of all staff.

Purchase of machines with robotic arms

2020

In 2020, Idroteck invests in industrial automation with the purchase of new machines equipped with robotic arms. This step impoves the efficiency and precision of production processes, strengthening the company's ability to meet market demands with top-quality solutions.

Further purchase of production machinery

2021

2021 marks a further technological advance for Idroteck, with the purchase of innovative production machinery. These investments are fundamental for optimising production capacity and ensuring an even faster and more accurate response to customer requests.

Launch of the Cadenas configurator

2024

In 2024, Idroteck introduces the Cadenas Configurator, a cutting-edge tool that simplifies and speeds up the process of selecting hydraulic cylinders. The configurator allows designers to intuitively configure customised cylinders, producing PDF data sheets and 2D and 3D drawings in various formats. It also allows projects to be saved and quotes to be requested online, making design more efficient andcustomised.