Tie-rod hydraulic cylinders

Accessories

Categories

Cylinders

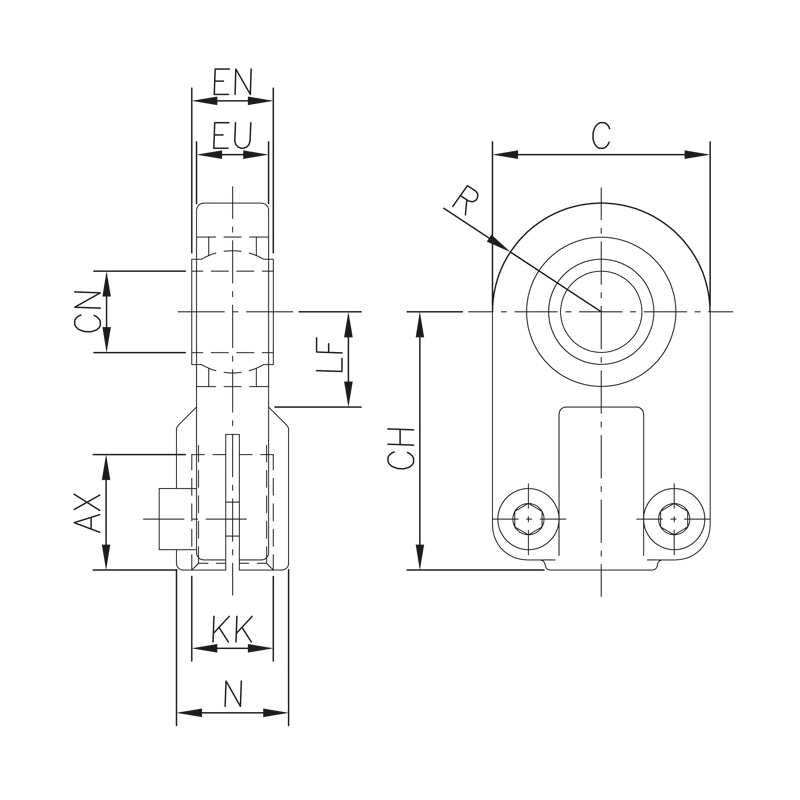

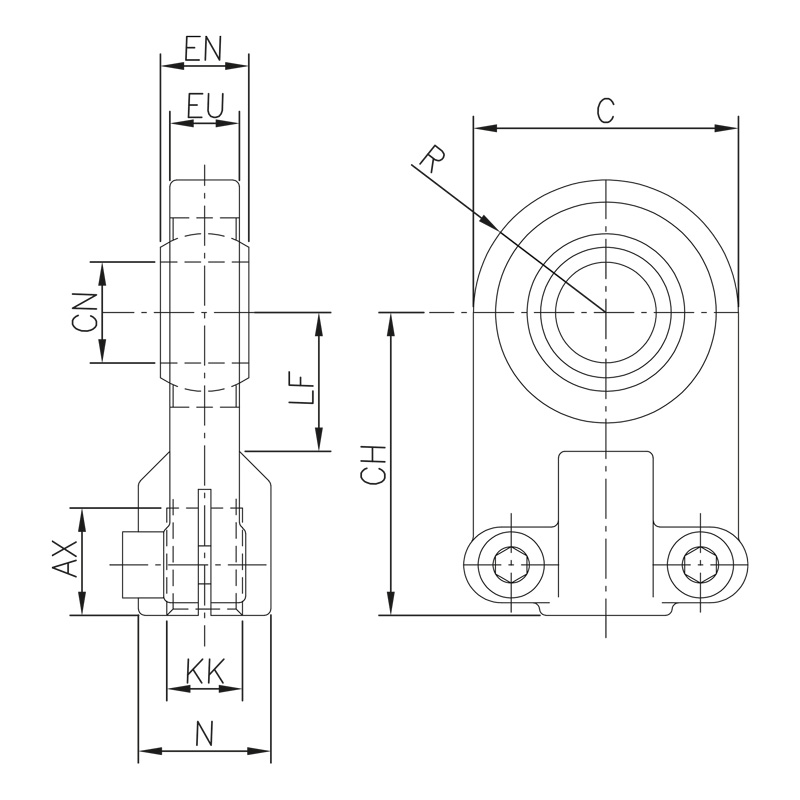

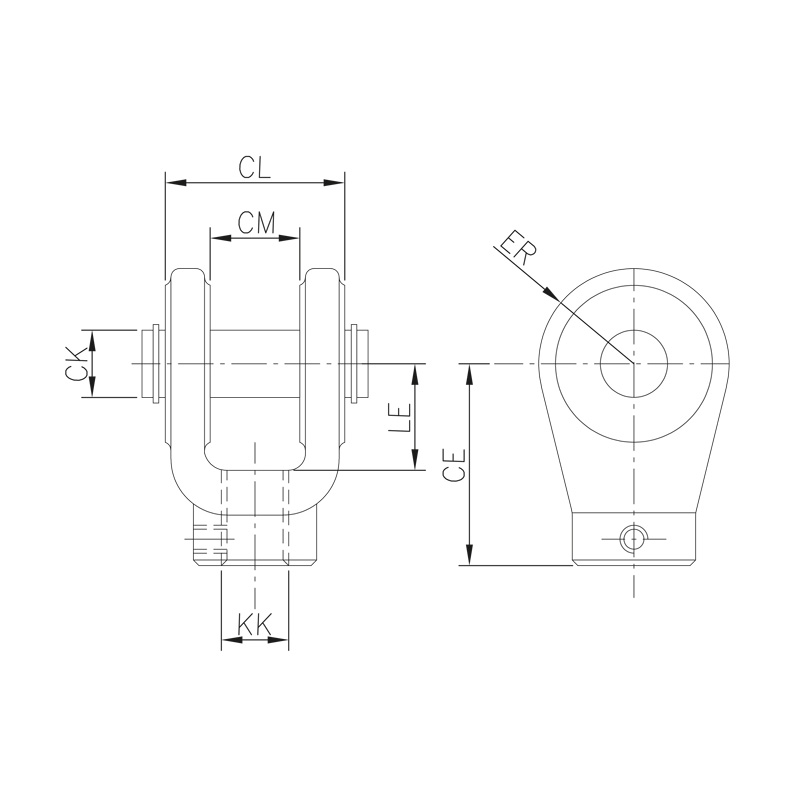

To ensure perfect coaxiality between the cylinder and the load being moved, while also assessing the considerable forces involved, Idroteck offers a wide range of accessories suitable for any end use of the tie-rod hydraulic cylinder.

Discover all the types of Idroteck end fittings, supports or pins.

Accessories

Discover all models